Engineering beyong furniture

Engineered as a single, seamless structure — where form reveals nothing, and engineering does everything.

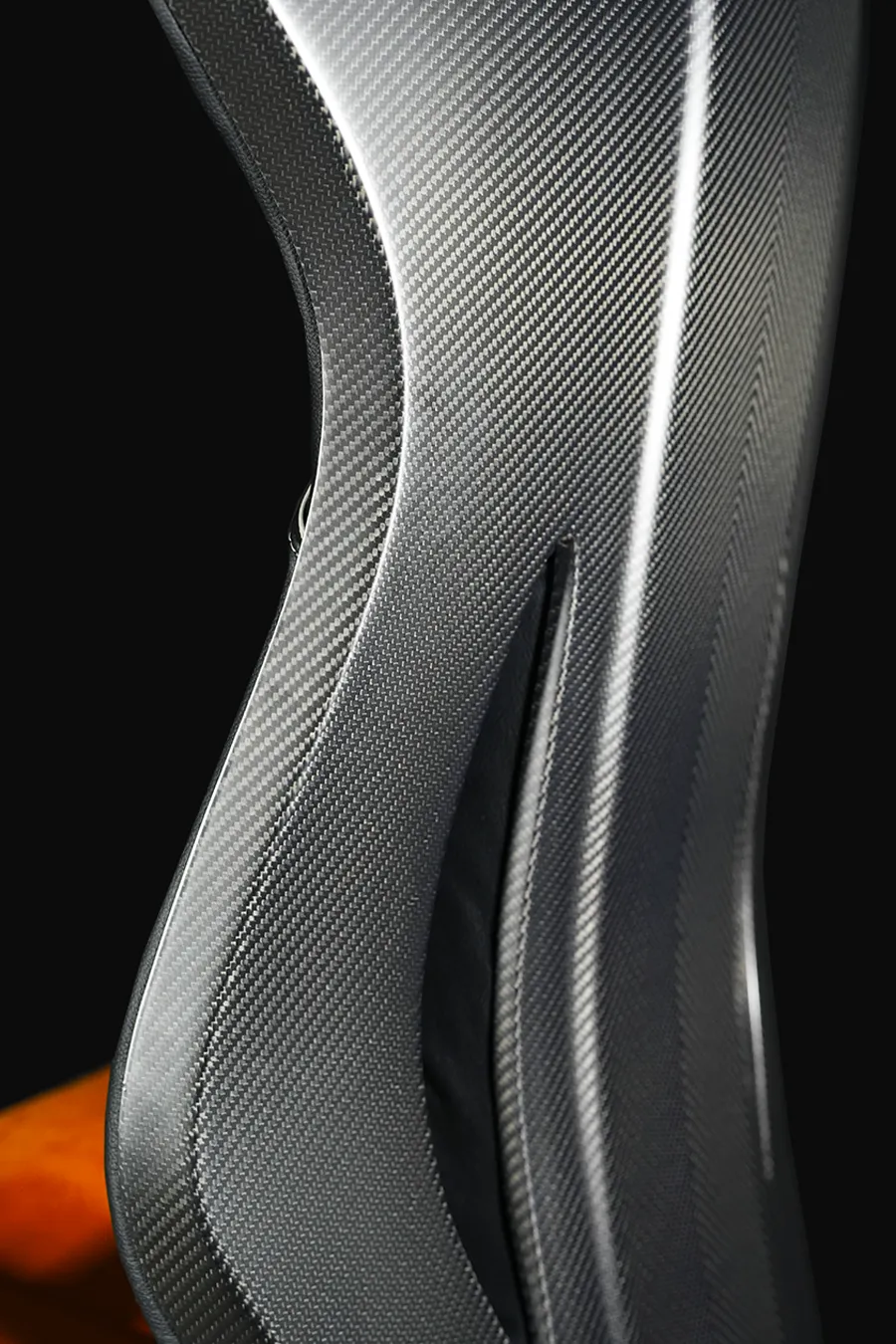

A Monocoque Philosophy

The Fiberseats One follows a monocoque design philosophy, where structure and form are inseparable. Unlike traditional chairs that rely on frames, brackets, fasteners, and decorative layers to conceal structural compromises, our chair is engineered as a single carbon fiber shell that carries the load, defines the shape, and delivers exceptional rigidity.

This approach eliminates visual clutter, removes visible screws and hardware, and results in a purity of form that cannot be achieved through conventional construction.

What you see is not a cover — it is the structure itself.

Carbon Fiber used for a Reason

Carbon fiber is not a stylistic choice for us; it is the very reason the Fiberseats One exists. We use aerospace-grade carbon fiber for its unmatched combination of strength, low weight, long-term stability, and design freedom.

Every layer, fiber orientation, and transition is engineered for performance and longevity, allowing us to create ultra-slim sections that remain rigid, responsive, and precise. This level of material intelligence enables structural solutions that are simply impossible with metal, plastic, or wood.

Ultra-Slim Architecture

Thanks to the inherent properties of carbon fiber, the Fiberseats One achieves an ultra-slim silhouette without sacrificing strength or comfort. Material is used only where it is structurally necessary, resulting in a lightweight yet exceptionally strong architecture with a visually floating appearance. The chair feels solid and precise while remaining refined and understated — a balance of strength and elegance that defines high-performance engineering.

Engineering for Comfort without Complexity

Comfort in the Fiberseats One is not achieved through visible mechanisms or mechanical complexity. Instead, it is engineered directly into the carbon fiber structure itself. The geometry of the shell, the controlled flex characteristics of the material, and the seamless integration of premium upholstery work together to provide natural support and long-term comfort. This structural approach allows for a clean, uninterrupted design where ergonomics are inherent, not added.

Engineering as the Foundation for Personalization

True personalization is only possible when the underlying engineering allows for it. Because the Fiberseats One is built around a carbon monocoque, we can offer extensive bespoke options — from different carbon fiber weaves and exposed finishes to custom paint patterns, exotic materials, premium leathers, stitching details, and personal engravings. The engineering defines the possibilities, and the artistry builds upon it.

Handmade in Germany

Every Fiberseats One is handcrafted in Germany by specialists experienced in carbon fiber manufacturing, motorsport finishing, and precision upholstery. From the initial carbon layup to final assembly, each chair is produced individually rather than on an assembly line.

This process ensures absolute control over quality, consistency, and detail, while enabling a level of craftsmanship and customization that mass production can never replicate.

Designed to Last

Carbon fiber does not fatigue like metal, warp like wood, or degrade like plastic. The Fiberseats One is engineered to maintain its structural precision, visual clarity, and functional integrity for decades. It is not designed for trends or short design cycles, but as a long-term object built with the mindset of a performance machine — something to be used, appreciated, and admired over time.

From Engineering to Experience

The Fiberseats One is more than a chair. It is the convergence of material science, structural design, and craftsmanship — engineered for those who value substance as much as style. Every curve, surface, and material choice serves a purpose, creating an object that performs as exceptionally as it looks.

Explore how this engineering becomes your personal expression.